Container Pricing: (NOTE: We are currently out of inventory for New and Used Shipping Containers)

(Covid 19 greatly reduced the manufacture of new containers to replace the used containers, causing the shortage and the price increases in red below)

New Orleans Depot

- 40ft DV(8.5ft high) or HC(9.5ft high)

- One Trip(New): $5200 ($7400)

- Used, Wind and Water Tight: $2600 ($5400)

- 20ft DV(8.5ft high)

- One Trip(New): $3200 ($5200)

- Used, Wind and Water Tight: $1800 ($3200)

- Other Fees

- Delivery: ~$200 to $400, depending on distance

- Tax: 9.45%

- No Credit Cards

- Visiting and Choosing a container onsite is highly recommended!

So you want a Shipping Container?

What makes shipping containers so appealing?

- DIY- Do It Yourself

- Place and Stack like children's blocks

- Cut out the contractor

- Create your own business niche

- Lower your carbon footprint

- A Premade Structure

- Wind and Water Tight

- Corrugated Steel Pattern

- Industrial Strength and Look

- Recyclable/Repurposable

- Modular

- Deliverable

- Stackable

- Modifiable

- Cost Effective

Reasons for wanting a Shipping Container?

- Storage

- A used shipping container can be purchased for approximately the same as one year at a storage facility

- Shipping containers are designed for ocean voyages and therefore offer protection from the elements

- The steel structure of a shipping container is a theft deterrent and very secure

- Dwelling

- The design and structure of a shipping container offers a maximum usable interior space

- Shipping containers are designed to be stacked offering the option of creating multi-level dwellings

What are the realities of Shipping Containers?

- Used vs New Shipping Containers

- A used shipping container is about half the cost of a new shipping container

- Used shipping containers are dented with a high probability of holes/leaking and contaminant residue from shipping usage

- New shipping containers have a complete inner and outer coating with no previous owner markings, dents, rust, etc.

- New shipping containers offer a variety of consumer amenities such as waist high door handles, lock boxes, extra venting, doors on both ends, etc.

- Note: New shipping containers are actually called 'One Trippers' and have performed at least one freight load to pay for transport

- Modifications

- Once a cutout larger than 2ft x 2ft on any of the side panels is performed, the vertical stability of the walls/rails decreases to the increase of the cutout

- Shipping containers require a steel craftsman for welding/fitting, torch/plasma/abrasive cutting, etc.

- Likewise, Industrial metal preparing and coating requires a similar sandblasting and painting craftsman

- Deconstruction with the added new construction can roughly double the labor involved

- Insulation

- Steel is an excellent thermal conductor- the temperature inside the container can be much colder or hotter than the exterior temperature

- The stability of the interior climate is greatly enhanced with proper temperature shielding on either interior, exterior or both

- Likewise, insulation is a must for climate control systems

- Utilities

- Plumbing is usually difficult when trying to meet code for shipping container dwellings and is moderately hindered by the steel corrugated walls and subfloor cross members

- Electricity is not as difficult when trying to meet code yet it may require added protective conduit

- Mounting, plumbing and venting solutions are required for HVAC systems

- Logistics

- Delivery of shipping containers are performed by tilt bed trucks such as a tow truck for 20ft or a Landoll for 20ft and longer containers. A 20ft shipping container delivery via a flatbed tow truck is less than the cost of 40ft+ delivery vehicle

- Delivery by flatbed trucks without tilting capabilities requires a forklift or crane for removal. Important to note that 9.5ft tall shipping containers cannot be transported on a standard 4.5ft tall flatbed because the overall height would exceed 13.5ft- a step deck flatbed would be required

- Shipping container placement is limited by the tilt delivery trucks- the longer the shipping container the more limiting

- Exacting placement and stacking also requires lifting capabilities such as a forklift or crane

- Size

- All shipping containers are 8 feet wide

- Standard shipping containers have two heights, 8.5 feet and 9.5 feet- the later more so with 40ft or longer shipping containers

- Standard shipping containers have a variety of lengths- 10ft, 20ft, 40ft, 45ft, 48ft and 53ft. The most common are 20ft and 40ft

Are shipping containers right for your project?

- Placement

- As a rule, shipping containers without structural modifications only need to be supported at the four corners preferably 6 inches or higher to prevent standing moisture and rodents from housing in the floor cross members. Likewise, enough room should be allowed for sub structure plumbing

- Tilt Bed delivery of shipping containers is limited to access, maneuverability, height and ground conditions. Cranes are required for exact positioning and stacking

- Shipping containers should be stacked corner casting on top of corner casting. Juxtaposing a shipping container on another by placing a corner casting on a main rail, top or bottom, will most probably result in structural failure

- Practicality

- Shipping containers are designed to open, close and lock from the outside

- Stacking other than corner casting to corner casting requires substantial reinforcements

- Community ordinances may prohibit and permits may not be available

- The delivery fee may be substantial over long distances

- The availability of contractors and craftsmen familiar with steel workmanship is limited

What to believe?

Truth vs Myth

- Myth- There are an abundance of cheap used shipping containers for sale

The Steamship industry sells off aged and damaged containers to middlemen brokers who in turn add their respective costs/fees/markup/taxes to the retail market

- Truth- Shipping containers make great storage facilities

The shipping container concept is easily adaptable to personal and commercial storage

- Truth- Shipping containers can be coverted into dwellings

Single and multi-level dwellings are common place in european countries, militaries and industries

- Myth- Modified shipping container dwellings are cheaper than conventional built dwellings

The modified steel shipping container actually is higher in cost than a constructed dwelling of comparable size

- Myth- Shipping containers are discarded and not recycled or repurposed

The life of a shipping container spans steamship usage, the retail aftermarket and then metal recycling

Are you ready?

Dwelling Cost Considerations

- Modifying or Remodeling per TEU (Twentyfoot Equivalent Unit)

- Modifying a Shipping Container is more like Remodeling or Adding to an Existing Structure

- The Cost to Remodel/Modify can be 1.5 to 2 times the Cost of TEU New Build

- Realize your Cost Threshold

- The overall Cost to Modify a TEU should be less than the Cost per TEU New Build

- The added Modifications and Delivery may not justify the savings compared to TEU New Build

- The Recycling Mindset will help you generate a Cost Threshold

- "...may be cheaper overall, but a New Build makes more sense..."

- "...is suffenciently cheaper overall, out-weighting a New Build..."

- Foundations

- Sub Structures such as Pilings, Concrete and Stairs cost the same

- Positioning onto the foundation is an added cost unlike New Build

- Connecting Mechanisms such as Steel Plates on top of the Piers are required

- Transportaion

- New Builds incorporate the shippings costs of building supplies in Price Per Square Foot

- Remodeling/Modifying Costs do not include Delivery or Positioning Fees

- The purchase site transportation fees increase with distance

Find a shipping container to purchase

- The Search

- Browse the internet

- Google Maps

- Craig's List

- Yellow pages

- Ask around

- If you are in the New Orleans region, call or visit us

- The Find

- First, the roof- No rust or puncture holes, Domed upward

- Second, the floor- No patchwork, No heavy delamination, No unknown coating, Screws secure, No uneven planks, No downward bow

- Third, the doors- No rust or puncture holes, Complete door gaskets, No tight door hinges or lock rods

- Lastly, the walls- No flatened corrugation, No heavy rust or paint pealing

- The Purchase

- Consider delivery and taxes

- If purchasing more than one, ask about a reduced rate per unit

- Inquire about modifications

- Do not purchase a used shipping container without inspecting first

Planning

- Verify

- Inform neighbors of your intentions

- Check with local zoning commisions

- Delivery

- Figure out which way you want the doors to be facing

- Make sure the delivery vehicle can manuver- clearance 10ft wide and 14ft high

- Make sure the ground is suitable to support the heavy delivery vehicle

- Place mounting blocks during delivery

- Coordinate the delivery of the lift vehicle closely with the arrival of the containers

- Position

- Level the container once in position to keep the doors in alignment

- Consider a solid foundation to mount the container

- Position where the container entrances are visible from main access roads

- Realise that the door lock rod cams need clearance to swing open

- Check ordinances regarding structure placement close to property lines

20ft & 40ft Dry Van Shipping Container

- The 20ft Dry Van

-

- The 40ft Dry Van

- Exact Exterior Dimensions:

-

- Width: (All) 95.875"

- Height: (All) 102" or "114"

- Length: (20ft) 238.50"; (40ft) 479.875"

- Exact Interior Dimensions:

-

- Width: (All) 93"

- Height: (All) 82" or 94", (Door Header: 78" or 90")

- Length: (20ft) 235"; (40ft) 476"

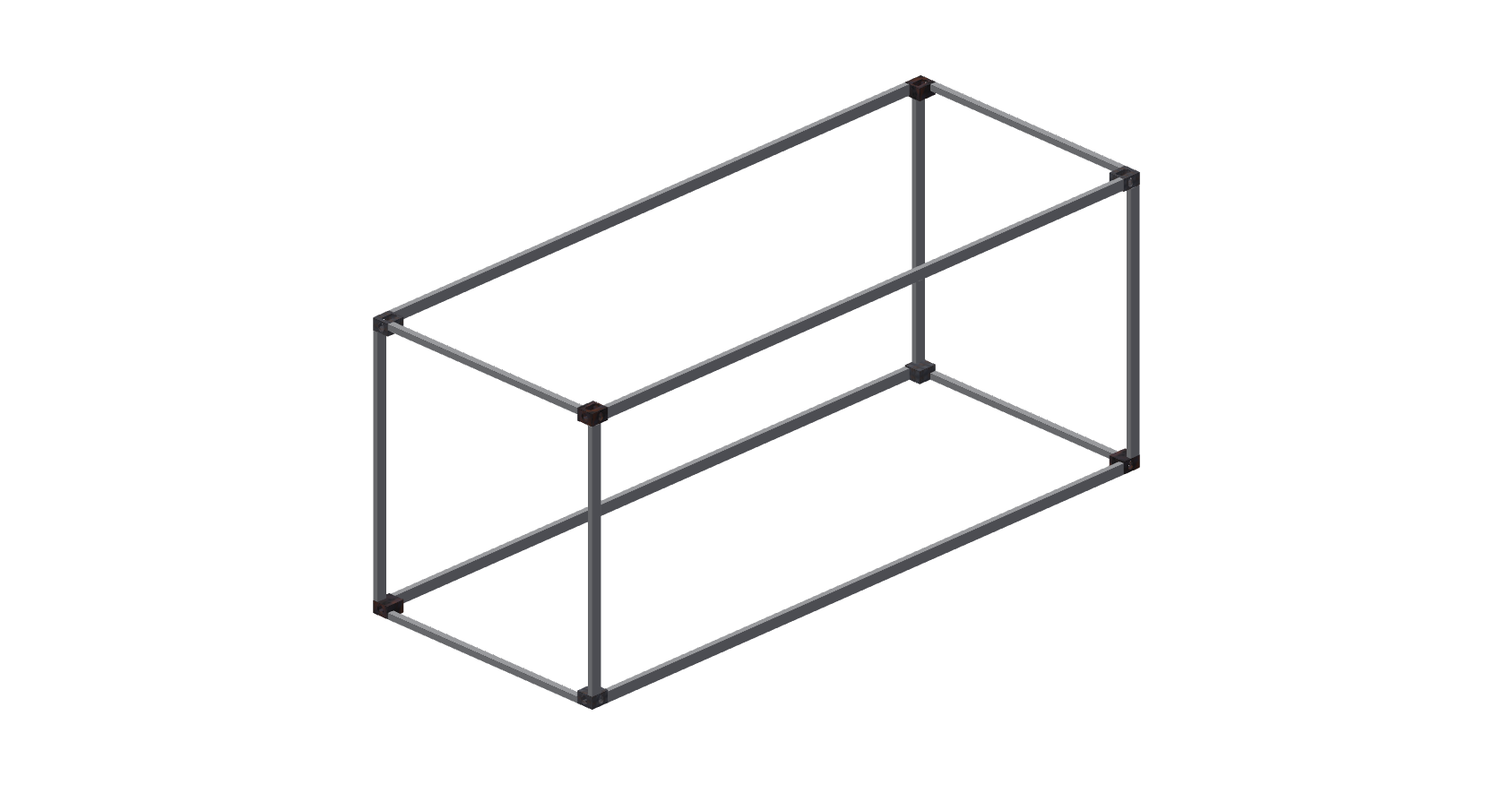

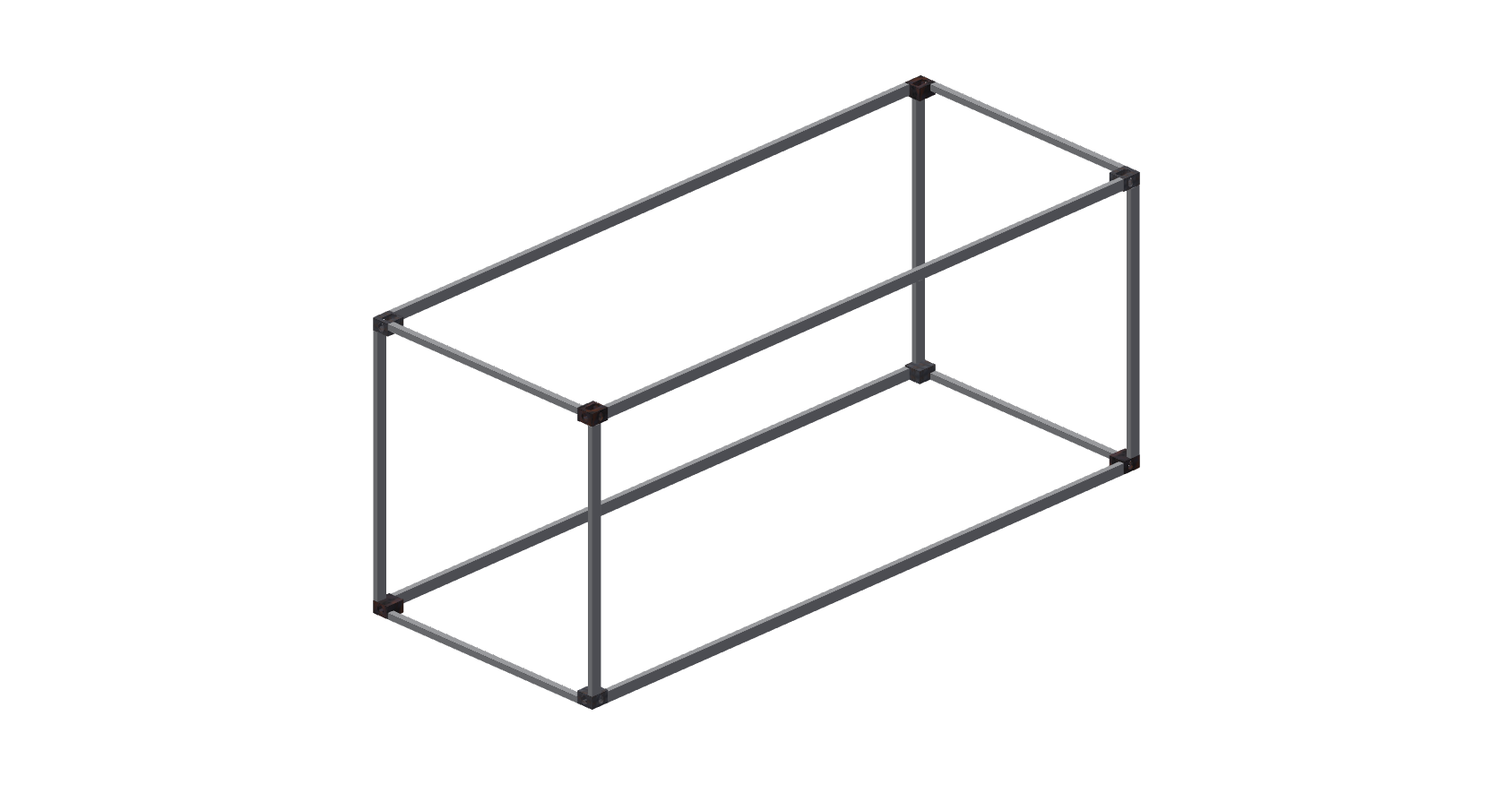

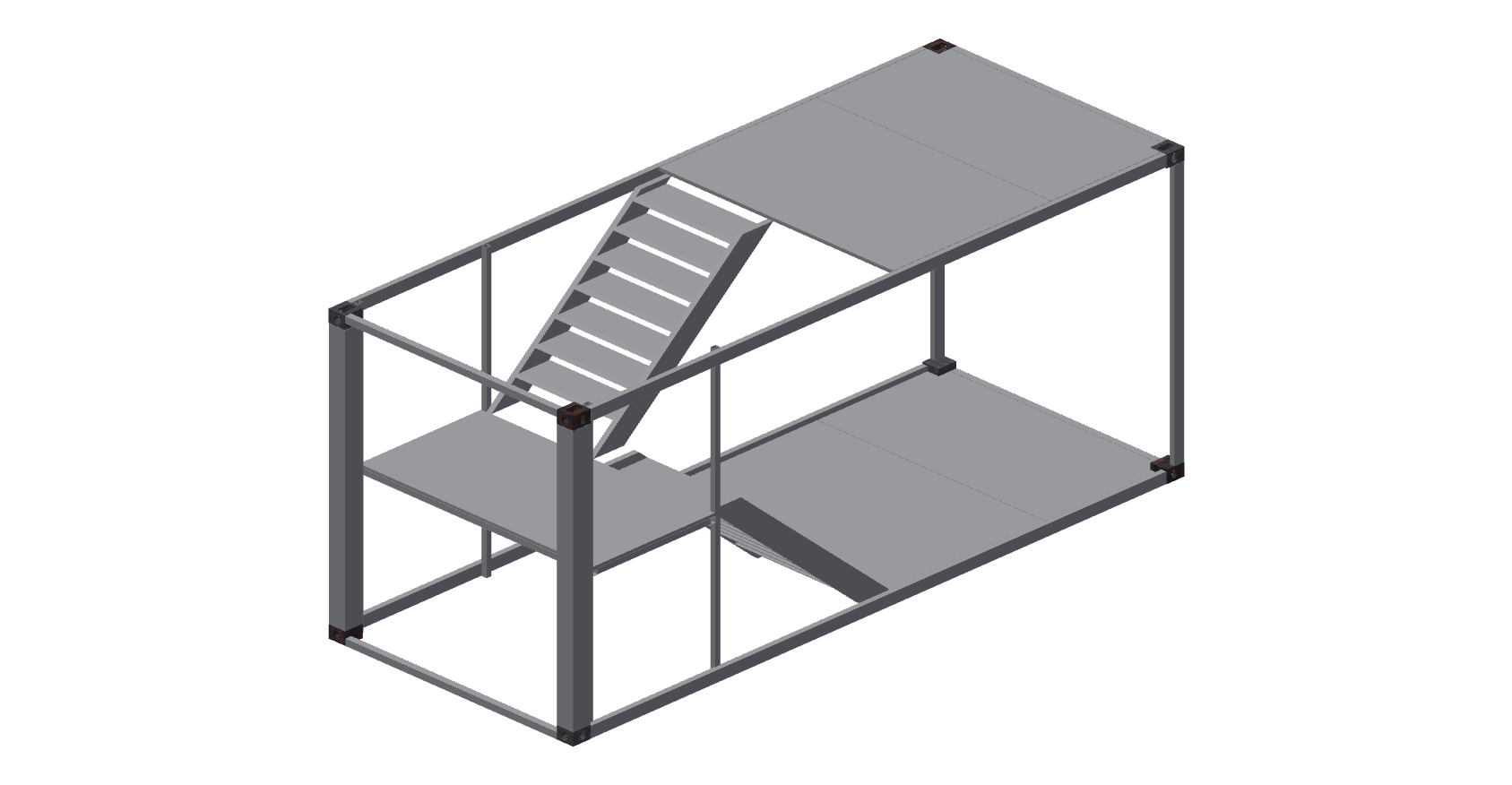

- The Rectangular Steel Frame is the Core Structure

-

- 8- Cast Steel Corner Blocks

- Top Rails are usually 10 gage Steel Tubing

- Bottom Rails are 10 gage Shaped Steel Plate

- Corner Posts are 1/4" Shaped Steel Plate

- All steel components are welded together

- The Panels are welded to the Core Frame

-

- 16 gage Steel Corrugated Side Panels are roll formed

- 16 gage Steel Corrugated Roof Panels are press formed

- 15 gage Steel Corrugated End Panels are also roll formed

- Bottom Rails and Sub Floor Cross Members are 10 gage Shaped Steel Plate

- Corner Posts are 1/4" Shaped Steel Plate

- The Doors provide Static Structure and Entry

-

- Forged Steel Hinges with hardened 1/2" Steel Pins

- 16 gage Steel Corrugated Panels and Tubing comprise the Doors

- Galvanized Steel Lock Rod Tubes have Cam Mechanisms, Lock Handles and Mount Bearings

- When closed, the Doors provide the same static reinforcement as the welded Front Panel for the Core Frame

- The Floor is the Base of the Core Frame

-

- 10 gage Steel C and Z Shape Crossmembers

- (20ft) 10 gage Steel Fork Lift Tunnel Crossmembers

- (40ft) 1/4" Steel Gooseneck Tunnel at Front End

- 21ply or 1.125" thick Treated Plywood

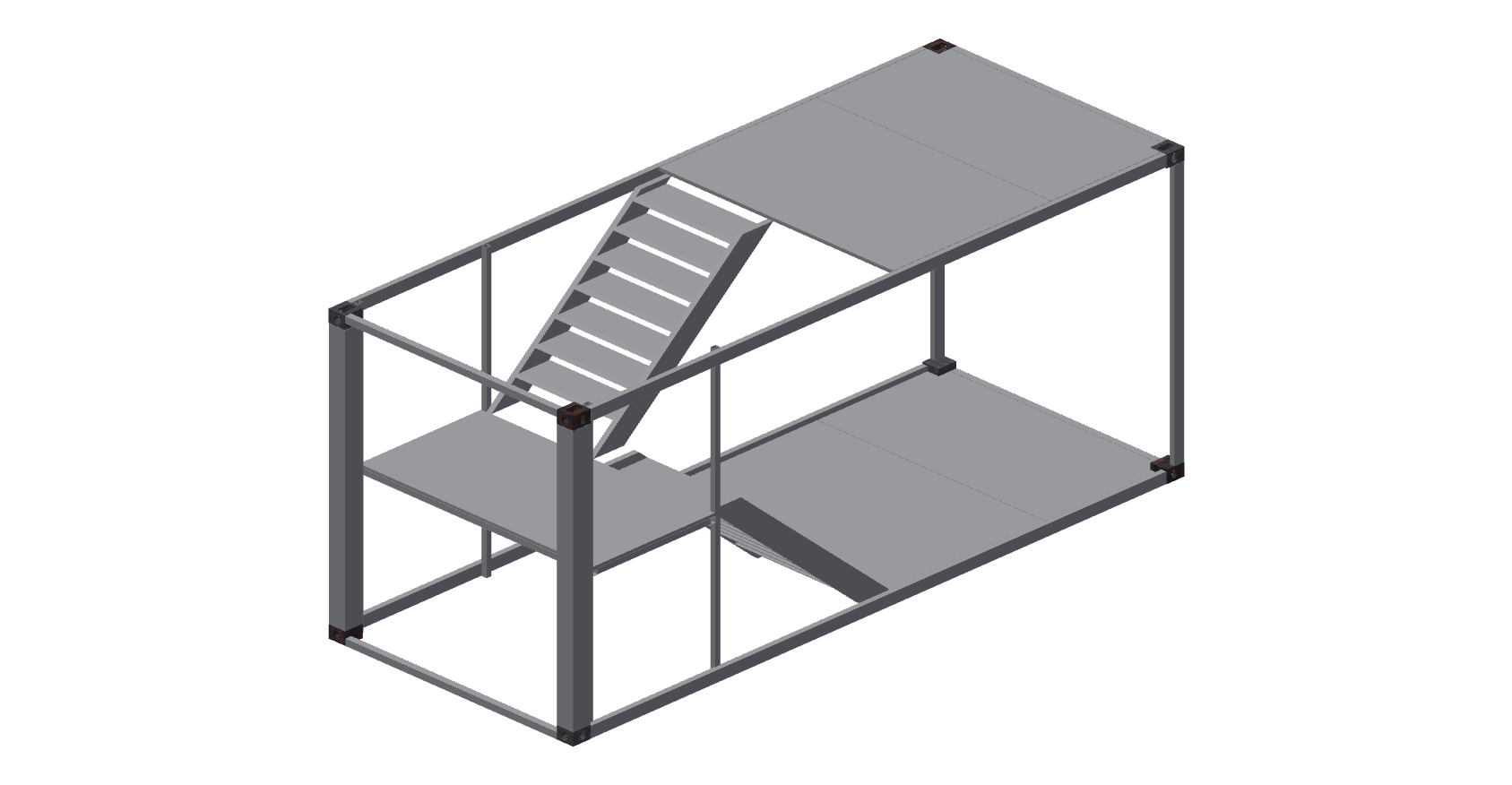

The Tank Frame

- The Basic Core Frame

- 20ft x 8ft x (8.5ft or 9.5ft)

- Loaded and Shipped like a shipping container

- Outfitted with a stairwell

- End rails allow the door cams to swing open unimpeded

- Side Corner Posts allow doors to swing to parallel

Skirt Adaptor

- 6" or 12" High by 20ft, 30ft or 40ft Long

- Uses:

-

- Mounting Platform

- Stacking

- Decking

- Juxtaposing

- Sub-Floor or Ceiling Plumbing, Venting, etc.

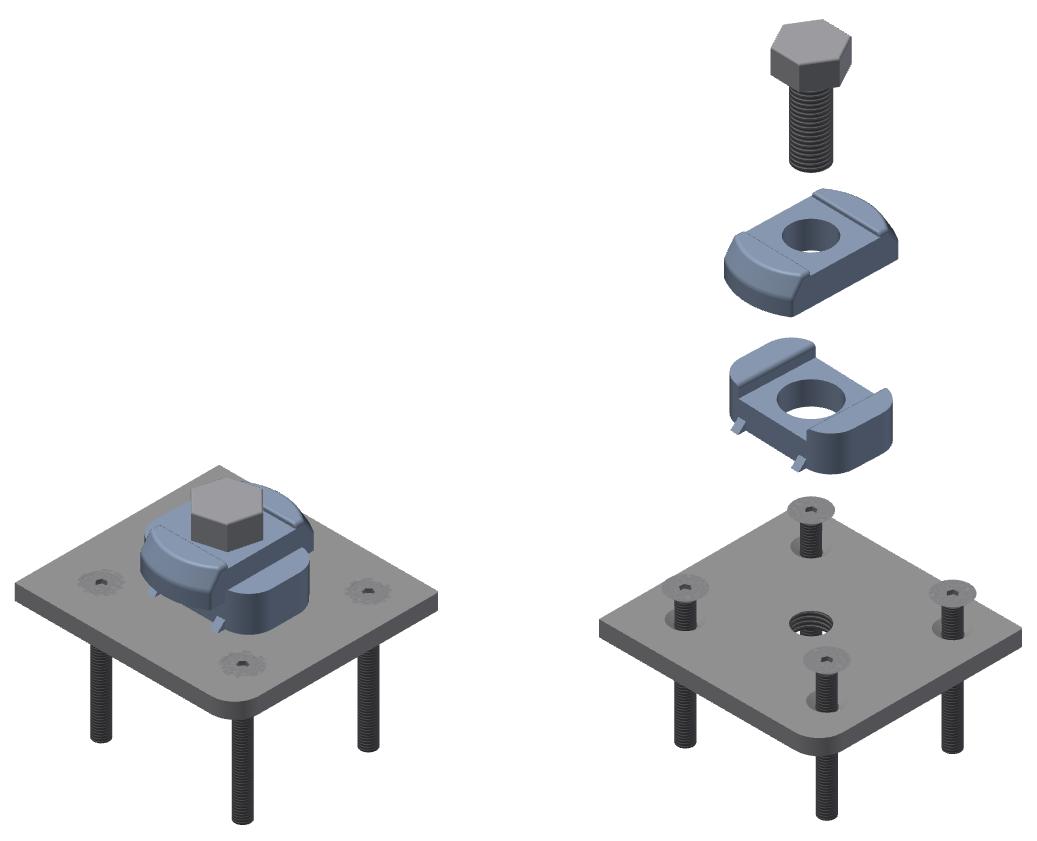

Corner Casting Lock

- Universal Lock

- Connecting Uses:

-

- Container to Container

- Container to Skirt

- Skirt to Skirt

- Once tightened, welding is also an option

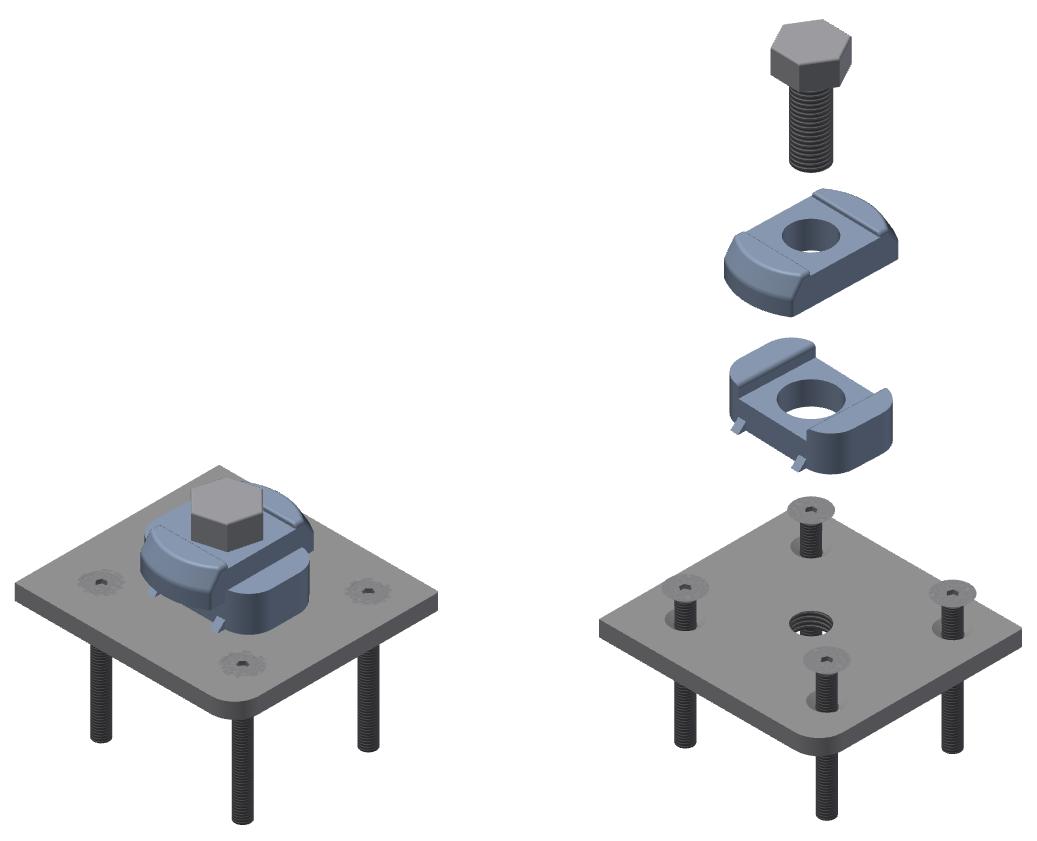

Base Mount

- Base Mount Lock

- Connecting Uses:

-

- Metal Substrate to Container Casting

- Concrete Substrate to Container Casting

- Wood Substrate to Container Casting

- For Steel Substrate, welding is an option

Panels

- Light weight aluminum panel with neoprene self adhesive backing

- Uses:

-

- Add an insulative layer to the both the interior or exterior

- Cover used/worn/damaged panels

- Maintain the corrugated industrial look

- Make a used container look new

- Simply peel and place

Framing

- Light gage steel tubing

- 1.5" x 3" x 16ga for side and roof panel

- 2" x 2" x 16ga for front end panel

- 2" x 3" x 11ga for container to container openings

- 2" x 4" x 0.25" for structural support beams

- Uses:

-

Foundation

- Support and Structure

- Helical Pilings

- Helical Piling Mount Plates

- Pier Mounts

20ft with Helical Piles, Slab, Piers, Skirt, Locks and Deck

20ft Slab, Piers, Skirts, Locks, Roof and Deck

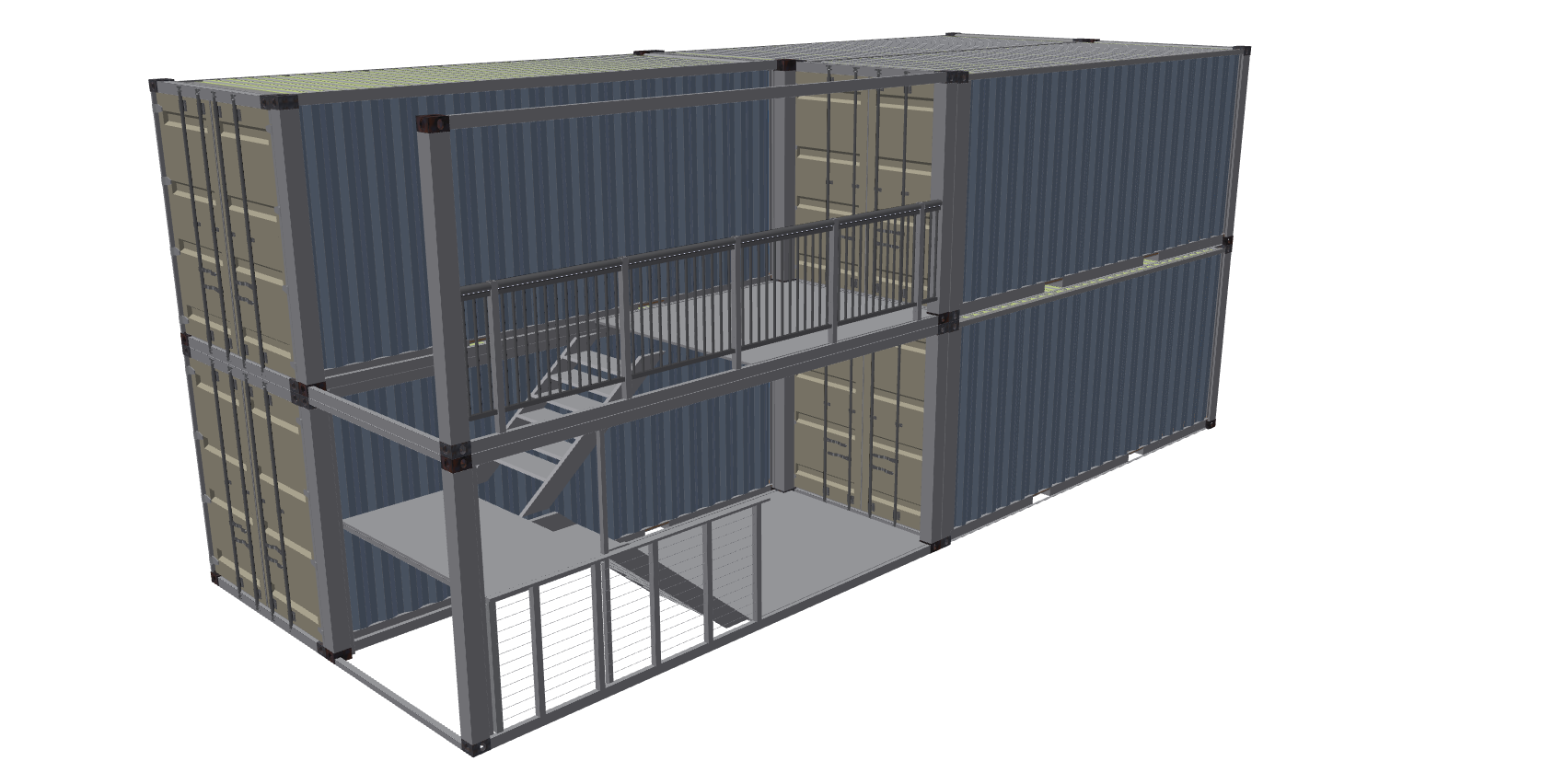

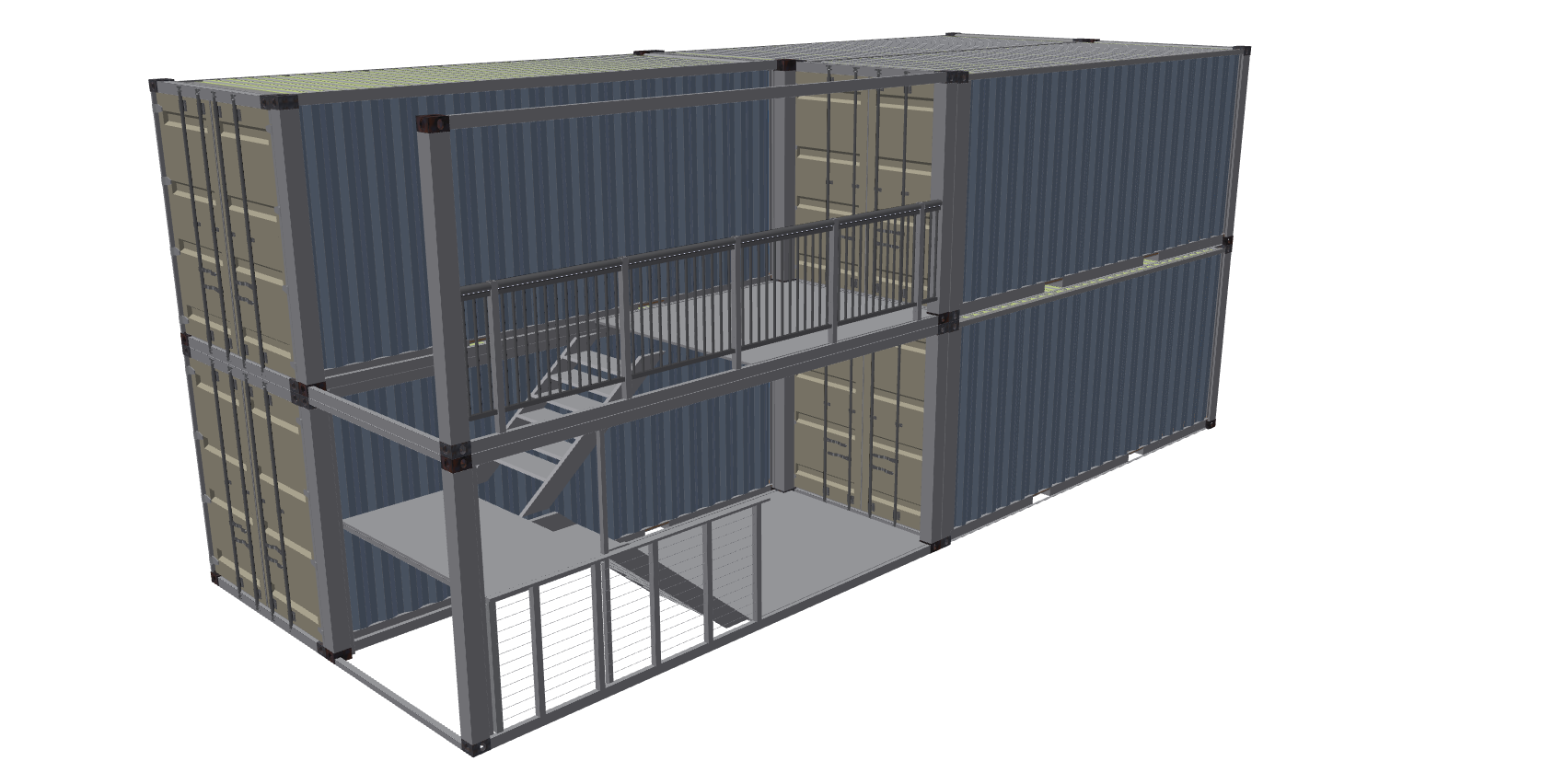

20ft's Stacked, Skirts, Locks, Stairs and Deck

20ft's Stacked, Stairs

20ft's Stacked, Stairs with a side stack

40ft's Stacked, Skirts, Locks, Stairs and Deck

New Orleans Depot is an Off Port Shipping Container Terminal

New Orleans Depot is an Off Port Shipping Container Terminal

- Facility

- 8 acres

- Crushed concrete base

- Two concrete load pad strips

- Centralized Maintenance and Repair Facility

- Large Covered/Enclosed Blasting and Painting Facility

- Services

- Single or Stackable Storage

- Empty Shipping Container Lifting/Stacking

- Gate Activity with Electronic Data updating

- Staging/Positioning equipment

- Maintenance and Repair

- Shipping Container Sales

- Equipment

- Taylor Empty Container Lift- Three High

- Taylor Empty Container Fork Lift

- Capacity Yard Jockey

- Sullaire Diesel Compressor

- 24 ton Sand Hopper with Blast Equipment

- Graco Paint Pump with Paint Equipment

- Refueling Equipment

- Torch, Plasma, Welding, Compressor, Tools, Etc.

- Rates

- Empty Container Storage

- Empty 20ft Shipping Container: $0.40/day

- Empty 40ft+ Shipping Container: $0.60/day

- Load (On Wheels) Storage

- Empty Container Lifting

- Gate Activity

- $6 per inbound inspection

- Or, $40 All Inclusive

- Empty Storage for Three Months, $1 per day after

- All Lifts

- All Gate Inspection Fees

- Contact Information

- Phone

- General/Sales: 888-310-6005

- Trucking: 504-248-9895

- Terminal: 504-242-6009

- Email

- Terminal: NODepot@nodepot.com

- Trucking: KWE@evansdelivery.com

- Container Sales: ContainerSales@nodepot.com

- Address

- Physical: 5690 Chef Menteur Hwy, New Orleans, LA 70126

- Entrance: 5610 Old Gentilly Rd, New Orleans, LA 70126

Evans Delivery, NOLA is our Intermodal Agency

Evans Delivery, NOLA is our Intermodal Agency

- Evans Delivery is based in New Orleans Depot Terminal

- 30 Power Only Trucks

- Servicing the Gulf South Region

- Trucking Rates

- 30 miles and below: $250 + Fuel%

- Above 30 miles: $1.55/mile + Fuel%

- OverNight, StandBy, HazMat, OverWeight and Chassis Fees Apply

- Contact

- Phone: 888-310-6005 or 504-248-9895

- Email: KWE@evansdelivery.com

New Orleans Depot is an Off Port Shipping Container Terminal

New Orleans Depot is an Off Port Shipping Container Terminal

Evans Delivery, NOLA is our Intermodal Agency

Evans Delivery, NOLA is our Intermodal Agency